UK company's orbital factory test brings space-made semiconductors closer to reality

A UK-based firm has moved the concept of orbital manufacturing from science fiction toward tangible industry, successfully testing a miniature factory in space.

Space Forge, headquartered in Cardiff, has confirmed its small, microwave-sized facility reached orbit and activated a furnace exceeding 1,000 degrees Celsius, a critical step for producing ultra-pure semiconductor materials in space.

The company asserts that the unique environment of space—characterized by microgravity and a near-perfect vacuum—offers transformative potential for manufacturing. Without gravity's interference, atoms within materials can form exceptionally ordered structures, while the absence of atmospheric contaminants allows for unprecedented purity.

“The work we're doing now is allowing us to create semiconductors up to 4,000 times purer in space than we can currently make here today,” said Josh Western, CEO of Space Forge. He highlighted potential applications in 5G infrastructure, electric vehicle chargers, and next-generation aircraft.

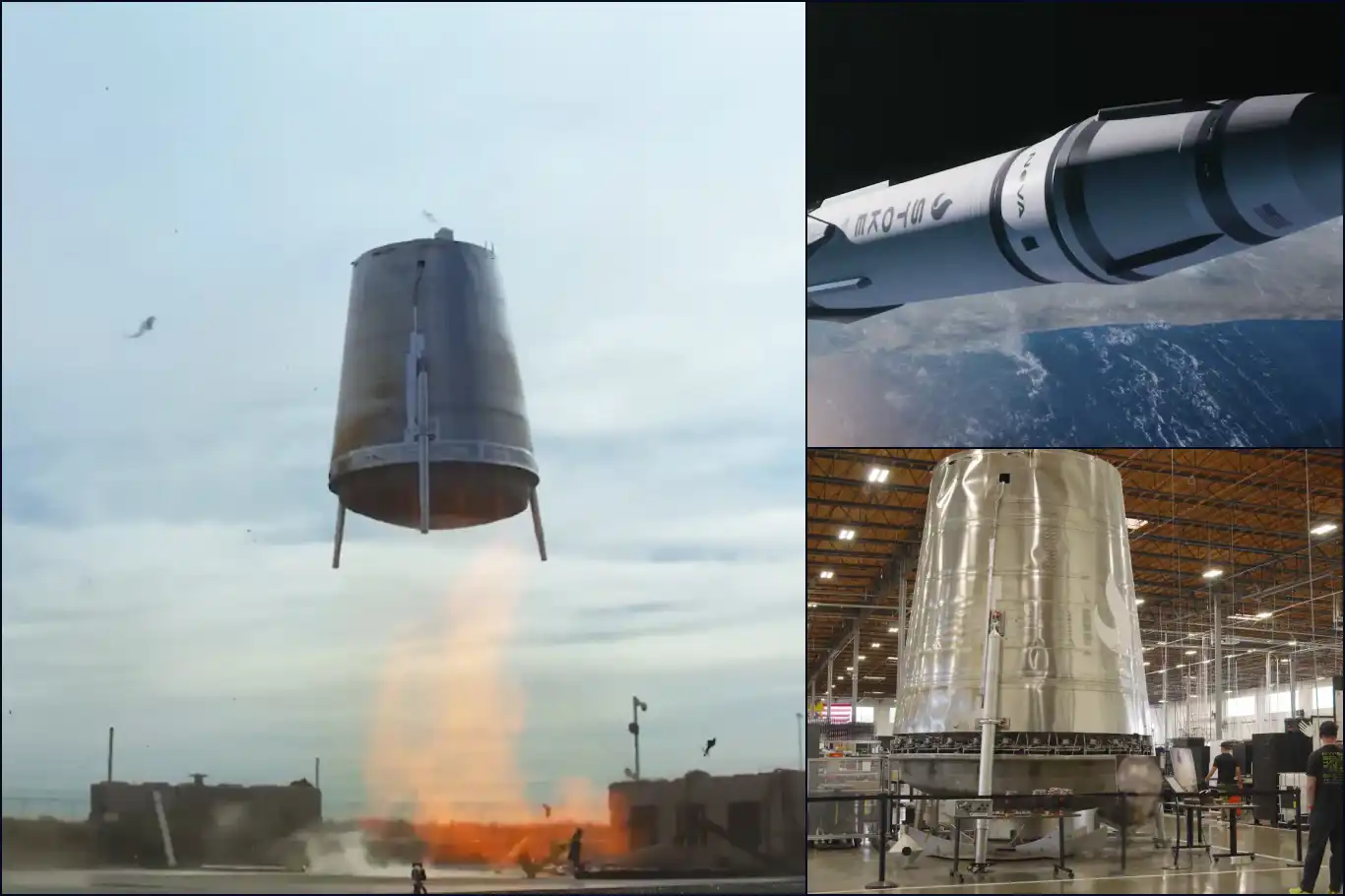

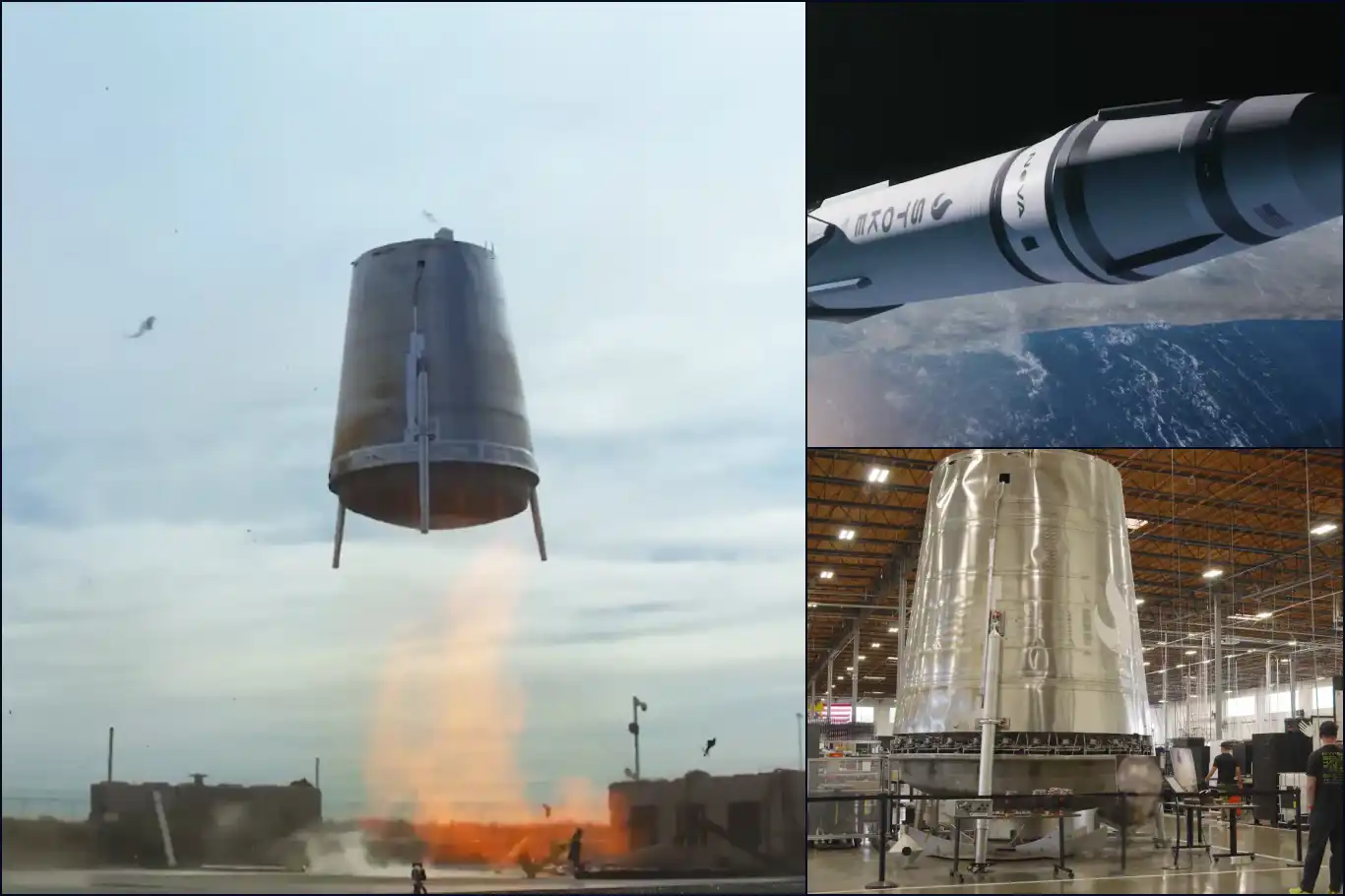

Launched aboard a SpaceX rocket earlier this summer, the mini-factory was operated remotely by engineers from the company’s mission control in Cardiff. A pivotal moment occurred when the satellite transmitted images from inside its furnace, showing a glowing plasma at the target temperature.

“This is one of the core ingredients we need for our in-space manufacturing process,” said Veronica Viera, Space Forge’s payload operations lead. “Seeing this working in orbit is incredibly exciting.”

With initial verification complete, Space Forge is now planning to scale its operations. The company is developing a larger orbital factory designed to produce enough semiconductor material for up to 10,000 chips per mission. A significant remaining challenge is the safe return of these delicate materials to Earth.

To solve this, the firm plans to test a novel heat shield named "Pridwen," inspired by the legendary shield of King Arthur. This technology is intended to protect the valuable cargo from the intense heat of atmospheric re-entry.

Space Forge is part of a growing sector looking to space as a new industrial base. Other entities are investigating the orbital production of pharmaceuticals, advanced alloys, and even artificial human tissues.

“In-space manufacturing is happening now,” said Libby Jackson, head of space exploration at the Science Museum. “We’re still in the early days, but proving the technology opens the door to economically viable products that can be made in space, returned to Earth, and benefit people everywhere.”

As these pioneering tests continue, the final frontier is increasingly being viewed not just as a realm for exploration, but as the next viable venue for high-tech manufacturing. (ILKHA)

LEGAL WARNING: All rights of the published news, photos and videos are reserved by İlke Haber Ajansı Basın Yayın San. Trade A.Ş. Under no circumstances can all or part of the news, photos and videos be used without a written contract or subscription.

A UK-based firm has moved the concept of orbital manufacturing from science fiction toward tangible industry, successfully testing a miniature factory in space.

U.S. astronomers have identified an extraordinarily rare cosmic system in which three merging galaxies each host an actively feeding, radio-bright supermassive black hole, offering unprecedented insight into how galaxies and black holes grow together over cosmic time.

OpenAI has announced the opening of a new senior position focused on managing the risks posed by advanced artificial intelligence systems, offering an annual salary of up to $555,000, underscoring the growing importance of AI safety and governance.